Getting Started: Strong Plastics

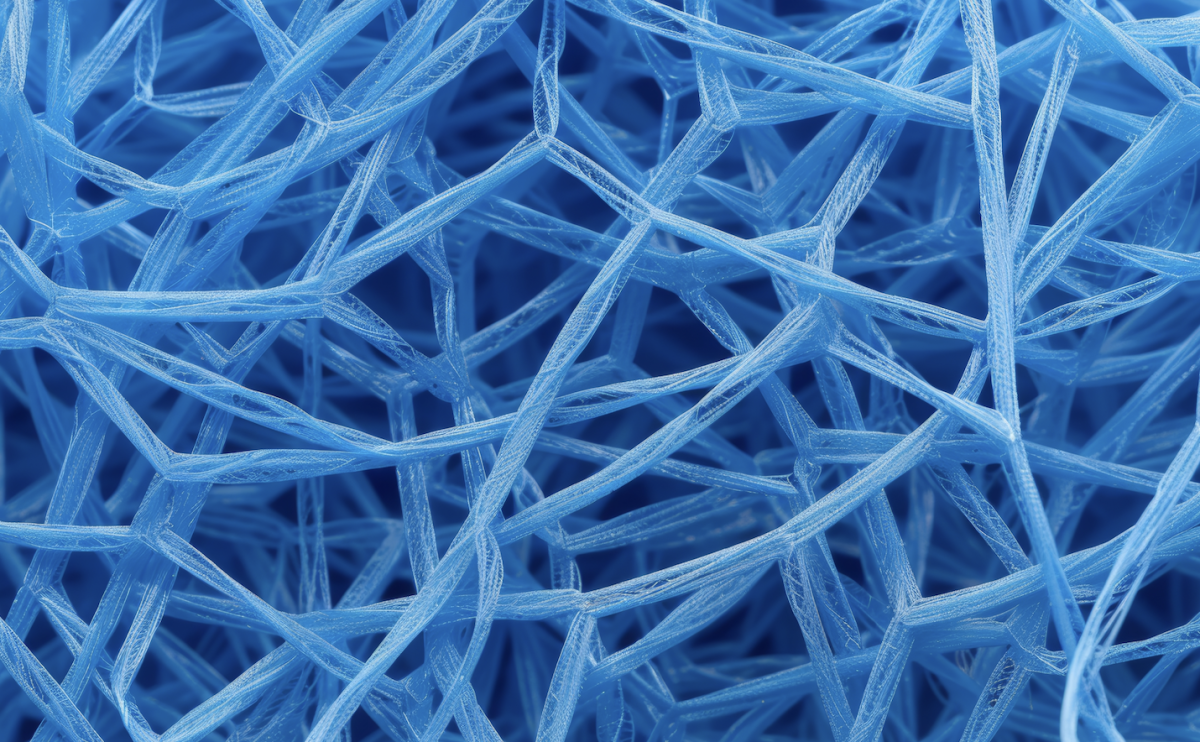

High-strength plastics like polycarbonate (PC), nylon (PA), and PEEK are essential for applications that demand durability and performance under stress.

The mechanical properties of these materials place them among the most durable and capable plastics in the injection molding market.

If you need injection molding services that hold up to the highest performance standards, JDI Plastics is waiting for your call. For over 29 years, JDI Plastics has provided high-quality injection molding services for industries across the board.

Early supplier involvement, product development, prototyping, and lifetime support - these are the advantages of working with an Injection Molding Company like JDI. Call today!

Key Takeaways

-

Strong plastics provide unmatched reliability for high-stress environments.

-

Polycarbonate, nylon, PEEK, and ABS are among the most durable plastics.

-

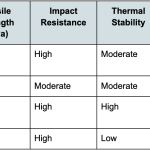

Key strength metrics include tensile strength, impact resistance, and thermal stability.

-

Common uses range from automotive components to protective gear.

-

The right choice depends on specific performance requirements for your application.

Plastic Strength Comparison Table

What Makes a Plastic Strong?

The strength of a plastic is determined by several factors: tensile strength, impact resistance, and flexibility.

Tensile strength measures the maximum stress a material can withstand before breaking.

Impact resistance evaluates its ability to absorb energy during sudden impacts.

Flexibility also plays a role, as overly rigid plastics can fail under repeated stress.

Thermal and chemical stability are equally important depending on certain product use cases.

Plastics like PEEK, which can resist high temperatures and harsh chemicals, are ideal for demanding environments. Manufacturers can evaluate these properties to select the material that best fits their specific project requirements.

Popular Strong Plastics for Injection Molding

Polycarbonate (PC)

Polycarbonate is celebrated for its high tensile strength and optical clarity. It’s an excellent choice for applications requiring durability and transparency. It is also resistant to impact, which makes it useful in environments prone to shocks or drops.

-

Common Applications:

-

Protective shields

-

Automotive headlamps

-

Electronic enclosures

-

Safety glasses

Nylon (PA)

Nylon combines impressive wear resistance with excellent tensile strength. It’s particularly effective for mechanical components subjected to friction and repeated use because it maintains its integrity under continuous stress.

-

Applications:

-

Gears

-

Bearings

-

Cable ties

-

Industrial fasteners

PEEK (Polyether Ether Ketone)

PEEK stands out for its exceptional strength and versatility. It offers unmatched thermal stability and chemical resistance. It is frequently chosen for aerospace and medical components where high performance is non-negotiable.

-

Key Advantages:

-

Maintains strength at high temperatures.

-

Resistant to a wide range of chemicals.

-

Excellent mechanical properties under stress.

Common Applications of Strong Plastics

High-strength plastics have revolutionized industries by replacing metals in demanding applications. Their lightweight yet durable properties improve efficiency and reduce costs across sectors like aerospace, automotive, and medical.

In aerospace, PEEK and polycarbonate are used in components that must endure extreme temperatures and stress.

The automotive industry benefits from the durability of nylon and ABS in parts like electronic connectors, buttons, and dashboards.

In the medical field, plastics like PEEK are ideal for surgical instruments and implants due to their resistance to wear and sterilization.

FAQs: The Strongest Plastics for Injection Molding

What is the best plastic for injection molding?

The best plastic depends on the application. PEEK is excellent for strength and heat resistance in aerospace or medical settings.

ABS is a more cost-effective option for applications prioritizing impact resistance, like consumer electronics or automotive interiors.

What are the top 5 strongest plastics?

-

PEEK: Exceptional strength and heat resistance for aerospace and medical uses.

-

Polycarbonate (PC): High impact resistance and optical clarity for automotive and protective gear.

-

Nylon (PA): Superior wear resistance, perfect for mechanical components like gears.

-

ABS: Excellent impact resistance and affordability for consumer and automotive applications.

-

UHMWPE (Ultra-High-Molecular-Weight Polyethylene): High toughness and abrasion resistance, ideal for industrial equipment.

What plastic should I use for injection molding?

The ideal plastic depends on your project’s specific requirements. PEEK is common for high chemical resistance and thermal stability, but it is typically much more expensive than lesser alternatives. Consider ABS or nylon for general-purpose applications with a focus on affordability.

Is PC better than ABS for injection molding?

Polycarbonate (PC) and ABS each have distinct advantages. PC is stronger and more heat-resistant, making it better for applications like protective equipment and automotive headlamps. ABS, on the other hand, offers superior impact resistance and is more cost-effective for everyday use in electronics and consumer goods.

Final Considerations: Strong Plastic Products From JDI Plastics

JDI Plastics is a high-quality, client-focused injection molding company with over 29 years of experience. We offer our clients a comprehensive and streamlined experience with everything from early supplier involvement to product development, prototyping, and mass production.

We offer lifetime support for the life of each product and always assure the highest quality service.

If you need a company that delivers the strongest plastics for injection molding tailored to your needs - JDI Plastics is standing by.

Call today!