Introduction to Injection Molding in the Automotive Industry

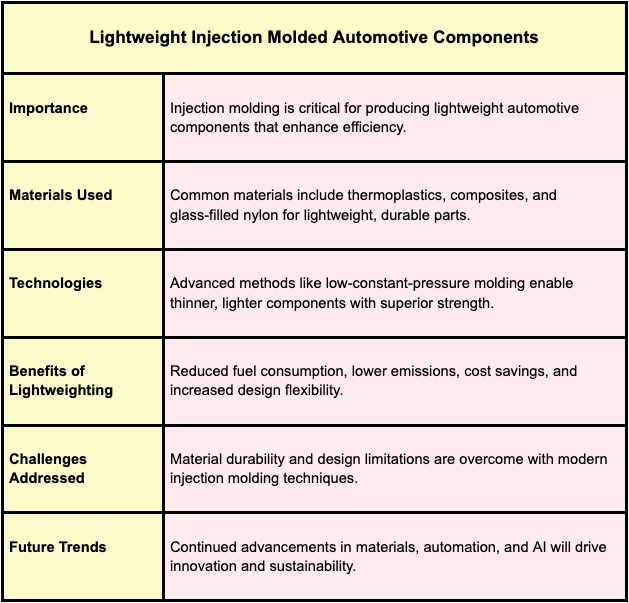

Injection molding is essential for producing lightweight automotive components that improve fuel efficiency, reduce emissions, and meet regulatory standards.

With the industry’s push toward more efficient, eco-friendly vehicles, injection molding has become essential for replacing heavier materials like metal with lightweight plastics and composites.

The old adage “less is more” applies here. Finding innovative and effective ways to reduce the weight of vehicles is in every manufacturer's best interest.

Innovation never rests, and JDI Plastics is here to provide your lightweight automotive components - backed by a commitment to the highest quality in plastic injection molding.

Key Takeaways:

- Fuel Efficiency: Lighter components mean vehicles consume less fuel.

- Emission Reduction: Lower vehicle weight results in fewer emissions.

- Regulatory Compliance: Helps manufacturers meet tough environmental regulations.

- Cost Savings: Reducing weight often lowers production and operational costs.

- Design Flexibility: Plastics offer more flexibility than metals in component design.

The Science Behind Lightweighting Through Injection Molding

Injection molding streamlines the production of lightweight automotive parts by using materials like thermoplastics and composites.

These materials are melted, injected into molds, and cooled to create durable, lightweight components. It is an efficient and precise process that is ideal for producing parts that must meet strict automotive standards.

Thermoplastics:

- Properties: Lightweight, recyclable, and versatile.

- Applications: Commonly used in interior panels, bumpers, and dashboards.

Composites:

- Properties: Strong, lightweight, and wear-resistant.

- Applications: Ideal for structural components and under-the-hood parts.

Glass-filled Nylon:

- Properties: Offers high strength and thermal stability.

- Applications: Often used in engine covers and air intake manifolds.

Advanced Technologies in Injection Molding for Automotive Applications

Innovative technologies are revolutionizing how we use injection molding in the automotive industry.

Low-constant-pressure molding is one such advancement. This allows for creating thinner, lighter parts without compromising strength. This technology reduces material waste and improves overall efficiency.

Another key development is the use of advanced polymers and composites. These materials, when paired with modern molding techniques, enable the production of components that are both lighter and more durable than ever before.

This shift is driving significant improvements in vehicle design by allowing for more complex and efficient structures that meet the rigorous demands of today’s automotive market.

These advancements in injection molding support the automotive industry’s lightweighting goals and pave the way for more sustainable, efficient, and cost-effective manufacturing processes.

Benefits of Metal-to-Plastic Conversion in Vehicle Manufacturing

Switching from metal to plastic parts in vehicle manufacturing is a smart move that brings multiple benefits. Injection molding allows manufacturers to create plastic components that can significantly reduce the weight of vehicles.

This weight reduction leads to cost savings, improved fuel efficiency, and a more environmentally friendly production process.

- Decreased emissions: Lighter vehicles produce fewer emissions.

- Enhanced design flexibility: Plastics allow for more innovative designs.

- Manufacturing efficiency: Streamlined processes lead to faster production.

- Lower costs: Reduced material and production costs.

- Improved fuel efficiency: Lighter cars use less fuel.

Case Study: Injection Molding's Impact on Electric Vehicle (EV) Development

Enhancing EV Range with Lightweight Components

Reducing vehicle weight is crucial for extending the range of electric vehicles (EVs).

EVs with lightweight injected molded parts can travel further on a single charge without needing larger, heavier batteries. This directly enhances the vehicle’s efficiency and market appeal.

Meeting Sustainability Goals

Lightweighting through injection molding aligns perfectly with global sustainability initiatives.

Lowering vehicle weight not only reduces fuel consumption but also contributes to reduced greenhouse gas emissions. This makes injection-molded components a key factor in achieving stricter environmental regulations and sustainability goals set by governments worldwide.

Cost and Performance Advantages

The economic and performance benefits of using lightweight plastics in EV manufacturing are clear.

Plastics are generally less expensive than metals, and the injection molding process is highly efficient and lowers production costs. Additionally, these materials offer excellent performance that contributes to the overall durability and reliability of EVs.

Challenges and Solutions in Automotive Lightweighting

One of the main challenges in automotive lightweighting is maintaining material durability while reducing weight.

Traditional materials like steel and aluminum are strong but heavy. Modern injection molding techniques allow manufacturers to use advanced plastics and composites that offer the strength required without the added weight.

Another challenge is design limitations. Lightweight materials must still meet strict safety and performance standards. However, innovations in injection molding, such as low-constant-pressure techniques, are overcoming these limitations by allowing more complex and effective designs.

This balance between lightweighting and maintaining high performance is crucial for the future of automotive manufacturing.

The Future of Injection Molding in the Automotive Industry

The future of injection molding in the automotive industry looks promising with continuous advancements in materials and technologies.

We’re seeing a shift towards even lighter and stronger composites, more precise molding techniques, and smarter manufacturing processes.

Innovations like automation and AI-driven quality control are set to enhance efficiency and precision further, driving the industry toward more sustainable and cost-effective production methods.

As automakers demand lighter, more efficient components, injection molding will be at the forefront of these developments.

Conclusion: Injection Molding's Role in the Future of Automotive Lightweighting

Injection molding plays an indispensable and irreplaceable role in the pursuit of lighter, more efficient vehicles. As we've discussed, the ability to create durable, lightweight components is essential for meeting modern automotive demands like fuel efficiency and emissions reductions.

The future of automotive manufacturing heavily relies on these innovations.

JDI Plastics is your trusted partner in this innovative wave of manufacturing. With a commitment to quality and innovation, we're equipped to help manufacturers meet their lightweighting goals. Our expertise in advanced injection molding means you receive top-tier components that drive your success forward.

Contact Plastic Injection Molding Company JDI Plastics today!