3D printing is revolutionizing the manufacturing industry, particularly impacting plastic injection molding. Known for its precision and adaptability, this technology reshapes how products are designed and produced. Its integration into traditional manufacturing methods enhances efficiency, cuts costs, and opens doors to innovative design possibilities. The combination of 3D printing with plastic injection molding marks a significant shift, moving beyond incremental advancements to fundamentally redefine production strategies.

Key Takeaways:

- Revolutionary Impact: 3D printing is transforming plastic injection molding.

- Enhanced Efficiency: It brings unprecedented efficiency in manufacturing.

- Cost Reduction: Significant cost savings are achievable with 3D printing.

- Design Freedom: Offers unparalleled flexibility in design.

- Production Possibilities: Opens new avenues in production capabilities.

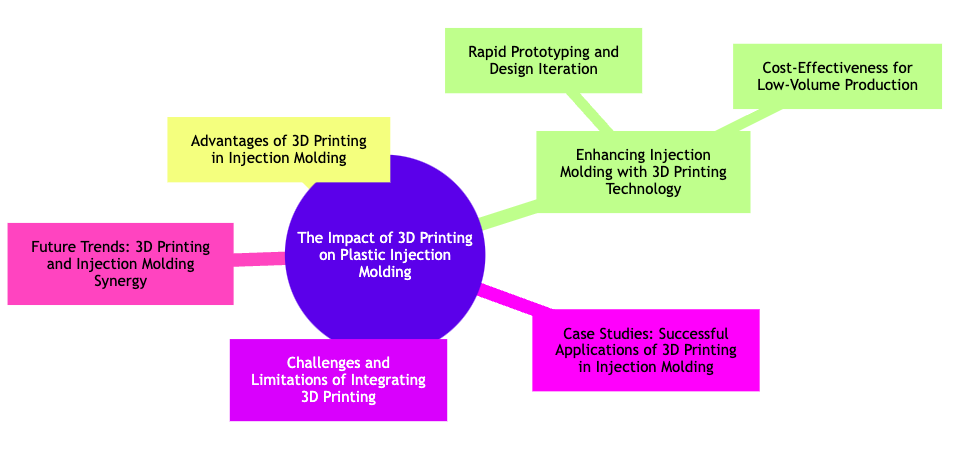

Advantages of 3D Printing in Injection Molding

3D printing introduces a host of benefits to the plastic injection molding process. It stands out for its rapid prototyping capabilities, allowing designers to bring their concepts to life quickly and efficiently. This speed in prototyping is crucial for testing and refining designs before mass production. Moreover, 3D printing offers unmatched design flexibility, enabling the creation of complex geometries that are challenging or impossible to achieve with traditional methods. This flexibility is a boon for customization and innovation in product design.

Comparison Table: Complementing Features of 3D Printing and Traditional Injection Molding

|

Feature |

3D Printing |

Traditional Injection Molding |

Complementary Benefit |

|

Speed of Prototyping |

Fast |

Slower |

3D printing accelerates initial design and prototyping, while injection molding streamlines mass production. |

|

Design Flexibility |

High |

Limited |

3D printing offers design versatility for initial concepts, which can then be efficiently scaled using injection molding. |

|

Complexity of Shapes |

Ideal for complex shapes |

Optimized for simpler, high-volume shapes |

3D printing handles intricate designs, and injection molding excels in producing simpler shapes at scale. |

|

Customization |

Easily achievable for prototypes |

Customization at scale |

3D printing allows for easy customization in the prototyping phase, and injection molding brings these custom designs to mass production. |

|

Cost-Effectiveness |

More cost-effective for low-volume |

More cost-effective for high-volume |

3D printing is economical for small batches and prototypes, while injection molding is more economical for large-scale production. |

Enhancing Injection Molding with 3D Printing Technology

3D printing technology significantly enhances the injection molding process. It introduces efficiencies in mold creation and prototype testing, reducing the time and cost associated with these critical stages. By leveraging 3D printing, manufacturers can quickly produce and test molds, accelerating the development cycle and enabling more agile responses to market demands.

Improvements Brought by 3D Printing:

- Faster mold production and testing.

- Reduced costs in prototype development.

- Enhanced design flexibility for molds.

- Ability to create complex mold designs.

- Quicker turnaround from design to production.

Rapid Prototyping and Design Iteration

3D printing empowers manufacturers with rapid prototyping, a crucial advantage in today's fast-paced market. This capability allows for quick iterations of designs, enabling teams to refine and perfect their products in a fraction of the time it takes with traditional methods. Rapid prototyping not only speeds up the development process but also ensures a higher quality of the final product, as designs can be tested and improved continuously.

Cost-Effectiveness for Low-Volume Production

One of the standout benefits of 3D printing in injection molding is its cost-effectiveness, particularly for low-volume production runs. This aspect is crucial for small businesses or for producing specialized components.

Cost Benefits:

- Reduced tooling costs for small batch production.

- Lower overall production costs for limited runs.

- Economical for producing customized or niche products.

- Savings in material costs due to precise production.

- Minimized waste in the manufacturing process.

By integrating 3D printing into plastic injection molding, manufacturers are not only streamlining their production processes but also opening doors to innovation and creativity in product design and development.

Challenges and Limitations of Integrating 3D Printing

Integrating 3D printing into traditional injection molding processes presents its own set of challenges. One significant hurdle is material compatibility. The materials used in 3D printing often differ from those in conventional injection molding, leading to issues in consistency and quality when combining these methods. Manufacturers must carefully select materials that are compatible across both processes to ensure product integrity.

Another challenge lies in scaling production. While 3D printing excels in prototyping and small-scale production, it struggles to match the high-volume output of traditional injection molding. This limitation can lead to bottlenecks when transitioning from prototype to mass production. Manufacturers need to strategize effectively to integrate these technologies without compromising on efficiency or output.

Case Studies: Successful Applications of 3D Printing in Injection Molding

The integration of 3D printing in injection molding has seen numerous successes. Real-world examples demonstrate how this synergy can lead to innovative solutions and enhanced manufacturing processes.

Case Studies and Outcomes

|

Case Study |

Description |

Outcome |

|

Automotive Parts |

Utilizing 3D printing for complex automotive prototypes |

Streamlined design process, reduced time-to-market |

|

Medical Devices |

Implementing 3D-printed molds for intricate medical devices |

Enhanced precision, customization capabilities |

|

Consumer Products |

Adoption of 3D printing for consumer product prototyping |

Increased design flexibility, faster product development |

Future Trends: 3D Printing and Injection Molding Synergy

The future of 3D printing and injection molding looks promising, with several trends and advancements on the horizon. We are likely to see more sophisticated integration of these technologies, leading to smarter, more efficient production methods. (1)

Predicted Developments:

- Advanced Material Compatibility: Innovations in materials that are versatile for both 3D printing and injection molding.

- Seamless Production Integration: Enhanced methods for integrating 3D printing into traditional manufacturing lines.

- Customization at Scale: Leveraging 3D printing for mass customization in injection molding processes.

- Sustainability Focus: Increased use of eco-friendly materials in both 3D printing and injection molding.

- AI-Driven Design Optimization: Utilizing artificial intelligence to optimize designs for combined manufacturing processes.

Conclusion: Embracing Technological Advancements in Manufacturing

In the ever-progressing world of manufacturing, the integration of 3D printing into traditional plastic injection molding signifies a pivotal shift. While 3D printing offers versatility and rapid prototyping, it's the enduring reliability and scalability of plastic injection molding that remains the cornerstone of mass production. This synergy of old and new technologies fosters an environment of heightened efficiency and bespoke customization, setting a new benchmark in manufacturing innovation. JDI Plastics, with its deep-rooted expertise in injection molding, plays a crucial role in this evolution. Their adeptness in harmonizing the steadfastness of traditional methods with the agility of 3D printing positions them as a leader in the industry.

JDI Plastics' commitment to this dual approach does more than just raise the bar - it redefines the possibilities within the manufacturing sector. Their focus on injection molding ensures the production of high-quality, durable products at a scale that 3D printing alone cannot yet achieve. This balanced focus on both technologies positions JDI Plastics not just as a participant in the manufacturing revolution but as a trusted leader, guiding the industry toward a future where flexibility, sustainability, and quality are paramount. As the industry continues to evolve, JDI Plastics stands ready, not only to adapt but to lead the way in this new era of manufacturing excellence.

References:

(1) Plastics Industry Association (PLASTICS)(, https://www.plasticsindustry.org/data-analysis-reports/global-trends/